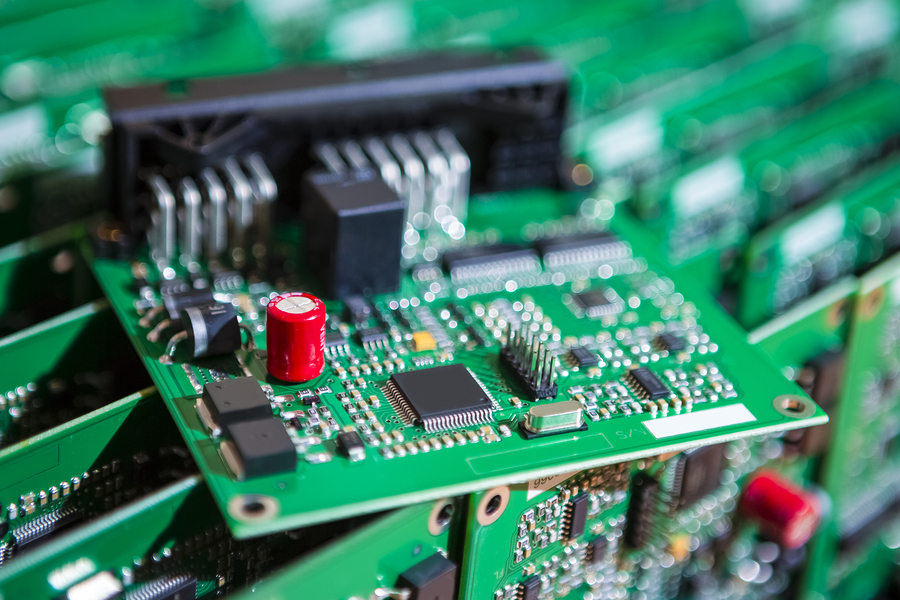

4 Ways of Reducing PCB Assembly Cost Without Sacrificing Quality

Many novice engineers will always try to find the most affordable circuit board assembly service. Their goal is to spend less on this vital service. Unfortunately, that is the last thing any experienced professional will consider. Neglecting quality and striving to find low assembly costs will result in the acquisition of faulty circuit boards. This will affect the quality of your electronic products. The devastation and loss caused by such an error can cause the closure of your manufacturing business.

Luckily, most PCB manufacturers are seeking ways of reducing production costs. That is a way of trying to attract clients to boost their profits. The PCB assembler that effectively balances customer service, quality, and the cost is the most attractive in the market. Listed below are effective ways to minimize PCB manufacturing costs while upholding the circuit boards’ quality.

Identify a Dependable Low-cost Assembler

The demand for PCB assembly services is on the increase. That has triggered the emergence of numerous PCB manufacturers claiming to offer quality services. Unfortunately, not all manufacturers deliver the best circuit boards. Most of them are simply making such claims with the intent of luring clients. Due to the competition for customers, some exceptional PCB assemblers are providing their services at an affordable price. By hiring such assemblers, you will get high-quality circuit boards at a low cost.

Optimization of Bare PCB’s Schematic Design

Before manufacturing the PCBs, the assemblers will carry out a DFM check. This process checks if you can use the circuit boards effectively. Many PCB manufacturers always provide free DFM check service, thus decreasing the assembly costs. The factors affecting the bare PCBs’ cost include:

- Layout count

- Surface Finish

- Shape and Size

- Via Tech

The bare PCBs result’s cost originating from comprehensive fundamentals will cause a slight fluctuation of the ultimate prices.

Prepare a Complete BOM

BOM is a list of items, components, sub-assemblies, assemblies, and raw materials needed for product manufacturing. Never assume creating a BOM is an easy task. Experienced specialists discovered most people make many mistakes when creating the BOM compared to Gerber files. A complete BOM will comprise necessary items for PCB manufacturing such as:

- Reference Designator

- Manufacturer Name

- Part Number

- SMT Method

- Comment/Note

- Case/Package

- Quantity

- Description

- BOM Level

In most cases, the PCB manufacturers have a template with BOM creating guidelines. That lessens the difficulty of filling it. This template also quickens the quotation process.

Make the Sourcing of Components Clear

Entrepreneurs with a small-sized companies find it challenging to control the project schedule and budget. Such persons should depend on the services of a PCB assembler. The PCB contractors have connections with franchised distributors. That is because they have transacted for a long time. Such a long-term business relationship allows them to get discounts when sourcing components. This relationship will save you money.

ChinaPCBOne Technology LTD. is the author of this article on PCB manufacturing. Find more information, about China PCB.